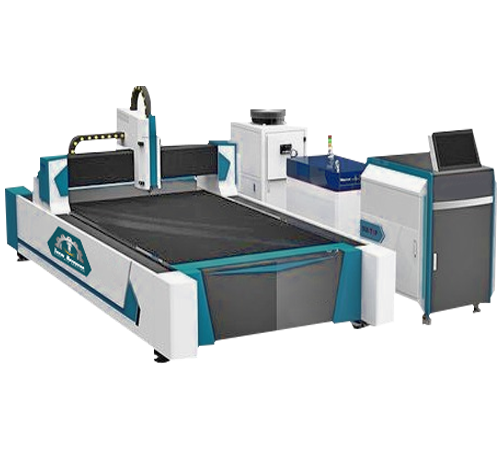

Fiber laser cutting machine is a high-precision CNC (Computer Numerical Control) equipment that uses a fiber laser source to emit a powerful laser beam for cutting, engraving, or marking metals and non-metallic materials. Unlike CO₂ lasers, fiber lasers use optical fiber doped with rare-earth elements (like ytterbium) to generate the beam, making them more efficient, stable, and cost-effective.

Fiber laser cutters are widely used in industries such as sheet metal fabrication, automotive, aerospace, electronics, and kitchenware manufacturing. They are known for high cutting speeds, low maintenance, excellent edge quality, and energy efficiency.